Droplet Impact Phenomena in Fluidized Bed Coating Process with a Wurster Insert

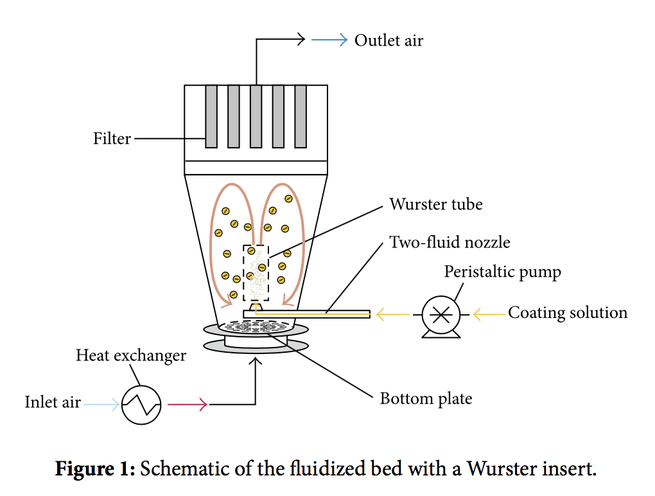

The aim of this study is to determine favorable process conditions for the coating of placebo tablets. Tablets made of microcrystalline cellulose are coated with hydroxypropyl cellulose polymer and Advantia™ Prime polymeric mixture film in lab-scale fluid-bed environment with a Wurster tube. In order to determine favorable process conditions (concentration, Wurster tube position, inlet air temperature, and atomization pressure), evaluation factors expressing process efficiency were calculated. Stereomicroscopy analysis provided good results with respect to the coating layer adherence and consistency. Results showed that the increased number of the coating cycles contributes to the desired featureless film morphology, when sufficiently high temperature and pressure are applied, thus resulting in high intra- and intertablet uniformity. Additionally, this paper analyzes the coating process from a mechanistic perspective of the underlying phenomena occurring on a tablet surface. Provided diagrams can help efficiently in detecting proper conditions that will result in coated tablets with strictly defined aimed properties. Process and formulation properties synergically result in a preferential occurrence of a deposition mechanism for all experiments conducted. Moreover, collision is found as a prevalent impact regime for the coating process studied. Finally, our intention here is to correlate hydrodynamic conditions and droplet breakup occurrence with a droplet diameter.