A novel approach to support formulation design on twin screw wet granulation technology: Understanding the impact of overarching excipient

Materials

Microcrystalline cellulose (Avicel PH101, Avicel PH105, Avicel PH301, FMC Biopolymer, Philadelphia, USA), α-lactose monohydrate (Pharmatose 200M, Pharmatose 350M, DFE Pharma, Goch, Germany and GranuLac 200, Meggle Group, Wasserburg, Germany) and mannitol (Parteck M200, Parteck Delta M, Merck, Darmstadt, Germany) were used as fillers. Hydroxypropyl methylcellulose (Pharmacoat 603, Shin Etsu, Tokyo, Japan) and polyvinylpyrrolidone (Kollidon K30, BASF, Ludwigshafen, Germany) were used as binders in this study. Croscarmellose sodium (Disolcel GF, Mingtai Chemical Co, Taoyuan Hsien, Taiwan), magnesium stearate (Mallinckrodt, St. Louis, USA) and colloidal silicon dioxide (Aerosil 200, Evonik, Rheinfelden, Germany) were used to prepare the final blend for tablet compression.

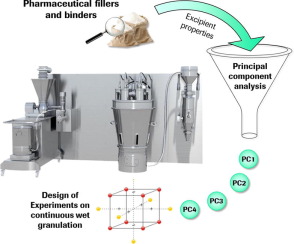

Conclusion

By combining PCA with DoE, the number of design factors and subsequently the number of experimental batches was reduced while a broad experimental space of filler characteristics was investigated in the same statistical design. The application of statistical models enabled to link granule and tablet characteristics with the overarching properties using DoE and with the underlying excipients characteristics using PCA (Figure 13). Thus, a good understanding was generated regarding how formulation impact the quality attributes of granules and tablets. The formulation understanding presented in this research work, as well as the statistical models can be used to support a lean formulation development: for example, excipients with appropriate characteristics can be selected in order to compensate for unfavourable API properties and thus the number of required experimental runs can be reduced. Furthermore, the predictive power of the model can be used for formulation optimization and troubleshooting, by selecting fillers and binders with appropriate properties to improve suboptimal granule or tablet characteristics. The scope of this study is limited to binary placebo formulations consisting of one filler and one binder type. In order to understand potential non-linear effects of filler mixtures on drug product properties, further studies would be required which could follow a similar approach. Furthermore, an understanding of the impact of the API properties on the drug product pCQAs is also of interest. One approach would be to characterize the API according to the applied methods for fillers and update the PCA model by including the API properties. Based on the resulting three principle component values for the API, the statistical model should allow qualitative predictions of the API effect on the drug product pCQAs.