Mechanistic modeling of a capsule filling process

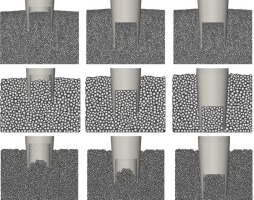

Filling a dosator nozzle moving into a powder bed was investigated using the Discrete Element Method (DEM). Various particle diameters and contact properties were modeled. The simulationsqualitatively showed the influence of powder properties on the amount of dosed powder. Two factors that influence the dosed mass were observed. First, the ratio between the particle and dosatordiameters affects the packing of particles inside the dosator chamber. Second, the flow behavior of the powder significantly modifies its filling and compression behavior. Cohesive powders pack lessdensely inside the powder bed, which could lead to a lower amount of dosed powder. In contrast, cohesive powders are compressed more during dosing and the density inside the dosator chamber increasesduring the dosing process. Since the simulation of fine cohesive powders is numerically impossible due to a high number of particles and small simulation time steps, we applied a simple method forparticle scaling to acquire a qualitative understanding of the filling behavior of coarse and fine powders.