Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review

The ICH quality vision introduced the concept of quality by design (QbD), which requires a greater understanding of the raw material attributes, of process parameters, of their variability and their interactions. Microcrystalline cellulose (MCC) is one of the most important tableting excipients thanks to its outstanding dry binding properties, enabling the manufacture of tablets by direct compression (DC). DC remains the most economical technique to produce large batches of tablets, however its efficacy is directly impacted by the raw material attributes. Therefore excipients’ variability and their impact on drug product performance need to be thoroughly understood. To help with this process, this review article gathers prior knowledge on MCC, focuses on its use in DC and lists some of its potential critical material attributes (CMAs).

Download the full article here

Continue reading here

About this article: Gregory Thoorens, Fabrice Krier, Bruno Leclercq, Brian Carlin, Brigitte Evrard, Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review,International Journal of Pharmaceutics, Volume 473, Issues 1–2, 2014, Pages 64-72, ISSN 0378-5173, https://doi.org/10.1016/j.ijpharm.2014.06.055. (https://www.sciencedirect.com/science/article/pii/S0378517314004840)

1. Introduction

The International Conference on Harmonisation (ICH) of Technical Requirements for Registration of Pharmaceuticals for Human Use has set a new quality paradigm as described in its guidelines Q8(R2), Q9, and Q10. The new paradigm promotes science and risk-based approaches to product development, dossier submission, review, inspection and post-approval change management. Furthermore, manufacturers are now encouraged to effect continuous improvement and technical innovation throughout the product life cycle.

The ICH quality vision impacts not only drug manufacturers but others in the pharmaceutical supply chain. Excipients, and therefore excipients suppliers, play an important and sometimes critical role with regard to drug product quality (Kushner, 2013). It is now paramount to identify, understand and control excipient variability, so that it can be compensated or controlled to deliver consistent product quality (ICH, 2005, ICH, 2009). Excipient performance is rarely fully understood (Moreton, 2009c, Wang et al., 2013) and at times underestimated (Carlin, 2012, Friedman, 2011). This is true even for one of the most popular tablet diluents used in the most straightforward process to produce oral solid dosage forms, namely microcrystalline cellulose (MCC) in direct compression (DC).

Direct compression (DC) is the tableting of a blend of ingredients without a preliminary granulation or agglomeration process. Despite involving only few process steps, product design in DC can be challenging because of the numerous competing objectives (Peck et al., 1990). Among several requirements, the compression mix has to flow to ensure a consistent tablet weight; it has to compress and compact into robust tablets; and the resulting tablets have to remain stable over time to maintain safety and efficacy. DC is directly impacted by material properties since these are not altered by preceding process steps. Therefore, direct compression requires increased performance, quality and consistency from the starting ingredients including excipients (Carlin, 2008, Kása et al., 2009, Patel et al., 2006, Tho and Bauer-Brandl, 2011). The use of poorly controlled or inadequately specified raw materials may lead to several challenges in DC, such as poor flowability and inconsistent tablet weight, unsatisfactory tablet strength, lack of content uniformity or segregation and dissolution failure (Friedman, 2011, Hentzschel et al., 2012, Ilic et al., 2013, McCormick, 2005, Patel et al., 2006).

Diluents are incorporated into tablet or capsule dosage forms to increase dosage form volume or weight, and as such they can also be referred to as fillers (USP37-NF32, 2014a). Some diluents, such as microcrystalline cellulose (MCC), can also be considered as dry binders since they improve the compactibility or tabletability of the compression mix. True DC binders are functional even at low use levels and offer superior tabletability (Carlin, 2008). Most DC grade excipients also offer superior flow compared to grades used in granulation techniques.

The scale of manufacture of excipients is very different from that typically encountered in pharmaceutical product manufacture. Indeed in continuous production, a ‘batch’ is usually a time period or slice (days) from a larger production campaign (weeks) (Carlin, 2012), but even days or weeks of production can still amount to many tons. Considering these large batch sizes and the intrinsic variability of continuous processes, intra-batch (container-to-container) variability is inevitable (Hoag, 2011, Moreton, 2006). For this reason, traceability of individual containers to the nearest relevant in-process results is essential. Additional excipient variability can be caused by (1) the seasonal quality variation of raw materials having natural origins and (2) the sourcing from multiple suppliers or from multiple sites, each of them using different processes (with or without processing aids), which may create issues due to performance disparities (Sheehan, 2012, Sheehan and Amidon, 2011).

The purpose of this review article is (1) to thoroughly describe MCC and its behavior in direct compression, (2) to highlight the need for a greater understanding of excipient variability and excipient performance, and (3) to gather prior knowledge relating to some possible critical material attributes (CMAs) of MCC when used in direct compression.

2. Microcrystalline cellulose, a direct compression binder

Microcrystalline cellulose (MCC) was discovered in 1955 by Battista and Smith and was first commercialized under the brand name Avicel® (FMC, 2013). In 1964 FMC Corporation introduced Avicel® PH to the pharmaceutical industry as an ingredient for direct compression tableting (Albers et al., 2006). MCC was first registered in the supplement to the National Formulary, twelfth edition, in 1966 (Suzuki and Nakagami, 1999). More than 50 years later, MCC is manufactured globally by more than 10 suppliers.

LIST OF MICROCRYSTALLINE CELLULOSE PRODUCTS AND MANUFACTURERS

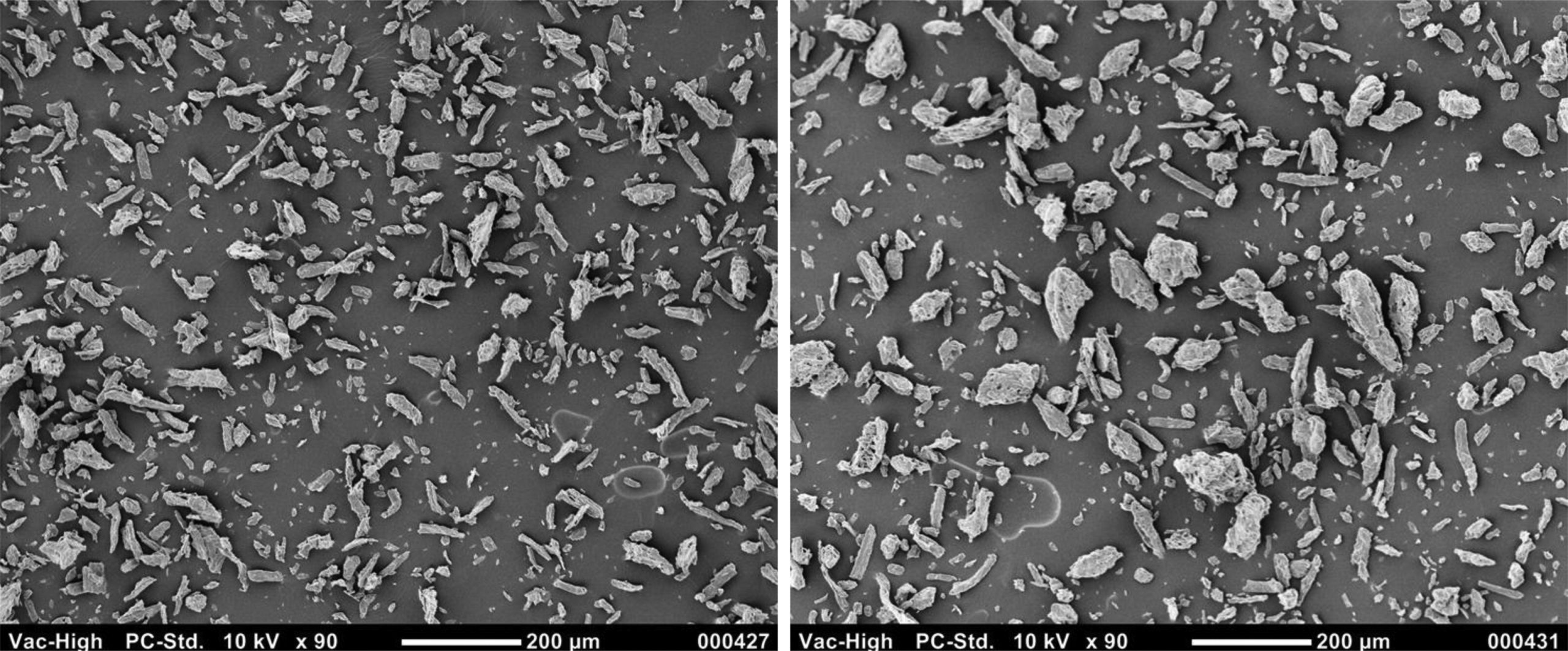

MCC is a purified, partially depolymerized cellulose prepared by treating alpha cellulose (type Iβ), obtained as a pulp from fibrous plant material, with mineral acids. Cellulose is the most abundant natural polymer on earth with an annual biomass production of 50 billion tons (Carlin, 2008). Cellulose consists of linear chains of β-1,4-D anhydroglucopyranosyl units.

The most common source of pharmaceutical MCC is wood, in which cellulose chains are packed in layers held together by a cross-linking polymer (lignin) and strong hydrogen bonds. Cotton has also been mentioned as a possible cellulose source for MCC (Shlieout et al., 2002, Suzuki and Nakagami, 1999). Both softwoods (evergreen conifer) and hardwoods (deciduous broadleaf) can be used (Landín et al., 1993a). These woods differ considerably in chemical composition (proportions of cellulose, hemicelluloses and lignin) and structural organization, i.e., regions which are relatively more crystalline or amorphous. The amorphous regions are more prone to hydrolysis so partial depolymerization by acid hydrolysis results in shorter and more crystalline fragments, i.e., microcrystalline cellulose.

More on Microcrystalline Cellulose

Gregory Thoorens, Fabrice Krier, Bruno Leclercq, Brian Carlin, Brigitte Evrard,

Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review,

International Journal of Pharmaceutics,

Volume 473, Issues 1–2, 2014, Pages 64-72, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2014.06.055.